HOT-DIP GALVANISING

Hot-dip galvanising involves submerging steel parts into a molten zinc bath to produce a protective coating over the steel, by an exceptional longevity.

The zinc coating is not merely deposited zinc, it is metallurgically bonded to the base steel through a metal diffusion reaction that occurs between the iron and zinc.

Centrifuging takes place immediately after removal from the bath, and the deposited thickness is from 50 to 90 µm.

LRD-TS mainly uses spinning for this treatment, in order to treat small parts.

Benefits

- Exceptional maintenance-free service life

- Full protection of the parts

- Dual electrochemical and physical protection

- The iron-zinc layer provides exceptional corrosion and abrasion resistance with good adhesion

- Unobstructed holes and drip-free parts

- The reliability of an industrial process complying with the NF EN 1461 standard

- A very cost-effective process

- Shiny parts

- Functional threads after treatment

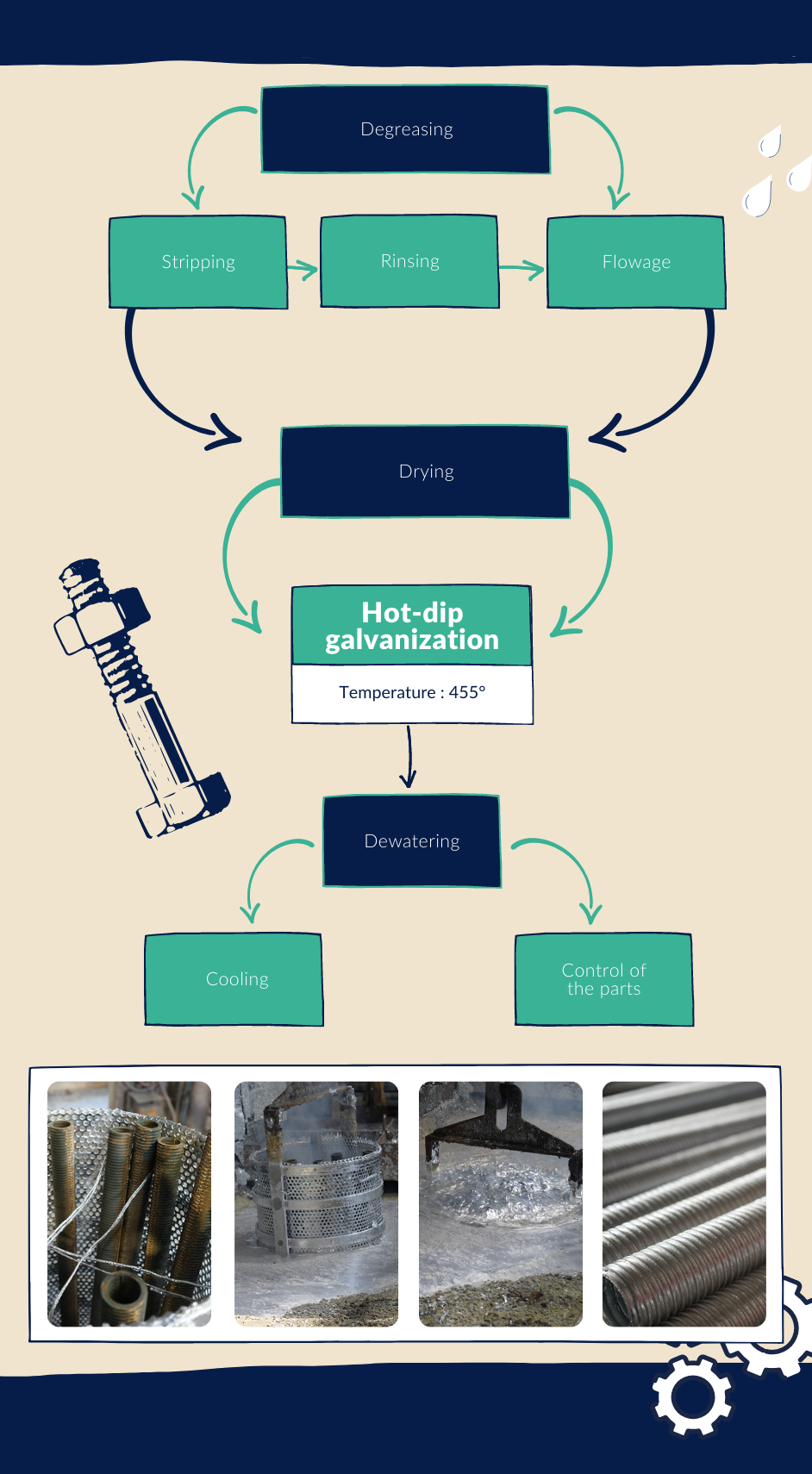

Reminder : Hot-dip galvanizing process

Applications

- Fittings for buildings

- Lag screws & threaded fasteners

- Nuts and bolts, construction, railway, etc.